Laser welding of thin sheet metal materialLaser Welding

we achieve highly tight laser welding,

with Nishimura Quality.

We now possess a high-performance laser welding machine, which enables us comprehensive processing of products, including manufacturing of metallic separators, battery cells, and battery cases. Welded portions are subjected to a cross-sectional visual inspection, or are verified by a leak test, to ensure quality welded products.

3D Single-mode Fiber Laser Processing Device

Laser oscillator

Model: YLR-500-AC-Y14 (IPG)

Output: 500W

Galvano mirror

Model: YD-3000ML-7.4 (Yasukawa Controls)

Irradiation area: 620×590mm

Can process material with the thickness of:

0.03~0.5mm

Capable of welding materials such as:

Titanium, Stainless steel, Aluminum, CFRP, General steel products, etc.

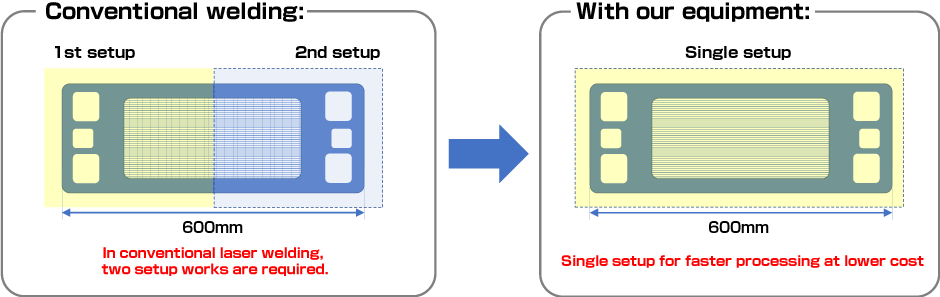

Reduce the number of required setups, lowering cost.

Integrated manufacturing from material procurement, to die making, press-forming, and welding all in-house.

Leave the entire bipolar plate manufacturing process to Nishimura. As your one-stop supplier from trial forming to mass production, we can provide complete bipolar plates with Nishimura quality. Not only do we make highly precise dies and manufacture excellent formed parts, we also provide in-house welding services. Rubber sealing is also available via collaboration with our partner suppliers. We support you to secure quality while reducing costs.

High quality welding

Reliable welding is achieved by using our jigs made in-house and adopting unique laser trajectory. Our joining expertise will help your work including development and test production.

+81-565-21-3579

+81-565-21-3579